IoT for Maritime and Logistics Efficiency

Modern maritime and logistics operations are under pressure to be more efficient. IoT offers a way to transform fleets by connecting ships, trucks, containers, and infrastructure.

With IoT companies gain real-time visibility into location, engine performance, fuel use, and environmental conditions. This visibility shifts operations from reactive to predictive. It also enables faster decision-making and reduced costs. Studies show IoT analytics can cut fuel use by 10–20% and maintenance costs by 20–30% and improve ROI. Dashboards and alerts help respond fast to engine overheating, water ingress and other hazards.

In this article we share why IoT matters in maritime/logistics. We provide key use cases, the technical underpinnings, and real-world case studies.

Why IoT Matters for Maritime and Logistics

Global Trade Demands

Shipping is the engine of world trade. ≈90% of goods move by sea. Customers and regulators now demand real-time visibility of cargo and greener operations. IoT provides a data like container sensors reporting location, temperature, shipboard gauges tracking fuel and engine health. So that operators no longer wait for port calls or paper reports. Experts project the number of IoT connections to surge from about 13.8 billion in 2022 to over 40 billion by 2034. Maersk, MSC, Hapag-Lloyd and other major carries have already equip fleets with IoT. They’ve done to automate operations and optimize routes.

Regulatory and Sustainability Pressure

IMO emissions caps and other regulations force shipping to cut fuel consumption and emissions. IoT sensors make compliance easier. They track engine output, fuel use, and exhaust gases and can alter speed or routes to cut carbon output. This yields significant savings and helps meet sustainability goals.

Safety and Risk Management

IoT enhances safety at sea. Sensors flag abnormal engine vibrations, overheating, or water ingress before they become disasters. Wearables and IoT communications also improve crew welfare. The net effect is fewer accidents and less downtime. IoT can reduce unexpected failures by detecting wear early.

Customer Service & Security

In logistics, shippers and customers demand transparency. IoT provides end-to-end visibility, building trust and reducing disputes. Sensors on cargo containers can trigger geofencing alerts when a unit goes off-course. For high-value or sensitive freight (like pharma), this real-time monitoring is invaluable.

Integration and Data-Driven Culture

Finally, IoT integration means disparate systems. ERP/WMS, AIS, weather services, and telematics feed into a unified platform. When live sensor feeds can be overlaid on maps, weather charts or even 3D ship models, managers get intuitive dashboards. IoT in maritime and logistics delivers the data-driven decisions.

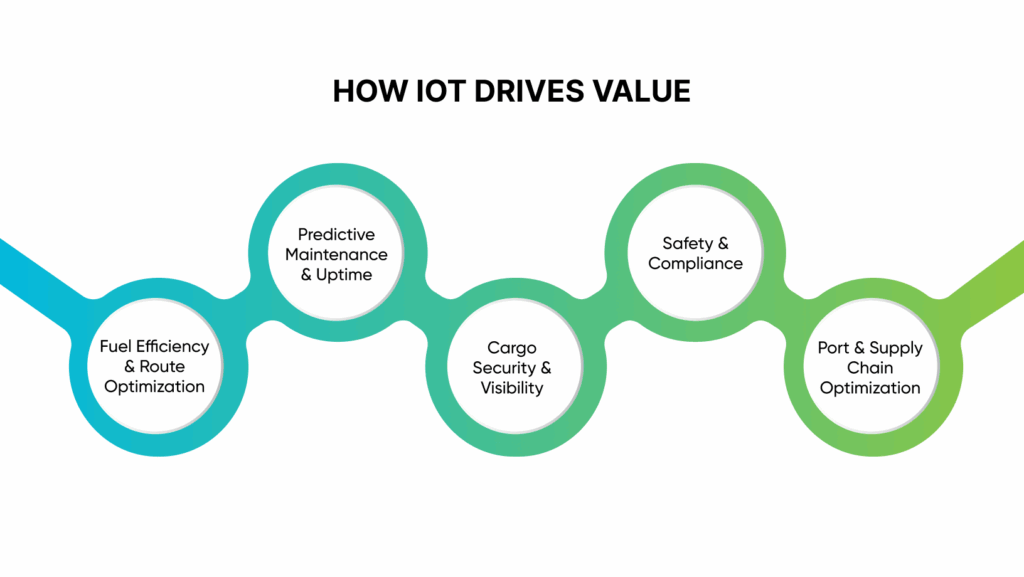

Most common benefits

Maritime and logistics companies leverage IoT in several high-impact ways:

Real-time fleet tracking and cargo monitoring

Smart devices on vessels, trucks, and containers report location and status. They can control temperature, shock, door open/close. Operators see live maps of fleet position, cargo conditions, and delivery status on dashboards. This visibility improves on-time performance, reduces losses, and bolsters customer satisfaction.

Predictive Maintenance & Uptime

IoT sensors collect engine telemetry (vibrations, temperatures, pressures) and system health data. Advanced analytics turn this into maintenance alerts before breakdowns occur. For example, Wärtsilä reports that its fleet monitoring solution has cut client downtime by up to 30%. Fleets using IoT often extend service intervals, avoid emergency repairs, reducing maintenance cost on ~20–30%.

Fuel Efficiency & Route Optimization

Continuous fuel flow and speed data allow automated fuel management. By adjusting speed, trim, and route based on live ocean and weather conditions, ships save fuel. One case saw a 15% fuel reduction in 12 months from IoT-based fuel tracking and optimized routing. Over a fleet, this translates to major cost savings and emissions cuts. Analytics help plan the cheapest routes and speeds.

Improved Safety and Compliance

IoT enables constant monitoring of critical parameters (hull stresses, hull girder strain, bilge levels, ballast water quality, etc.). Sensors on a hull can detect corrosion or leaks, triggering inspections before failures.

Emissions sensors ensure sulfur or CO₂ caps are never exceeded. And wearable IoT devices and communication systems protect crew by raising alarms in medical or emergency situations.

Asset & Cargo Security

Connected containers and cargo vans strengthen security. Door sensors and GPS geofences alert operators to unauthorized access or route deviations. For high-value freight, this means immediate action on theft or misrouting. Such monitoring also streamlines insurance claims and regulatory audits.

Smart Port and Supply-Chain Optimization

Networks of IoT devices track container movements, crane operations, and terminal equipment. This data optimizes berth planning and gate operations. Ports like Rotterdam use thousands of sensors to coordinate container flows and machinery. When combined with AGVs, automated cranes, operations speed up and costs fall.

Each of these use cases delivers tangible business benefits. For example, lower OPEX and CAPEX through fuel and maintenance savings, higher asset use, and reduced risk of accidents or fines.

Technical Architecture and Implementation Considerations

Building an effective IoT solution requires a thoughtful architecture spanning devices, connectivity, data, and interfaces.

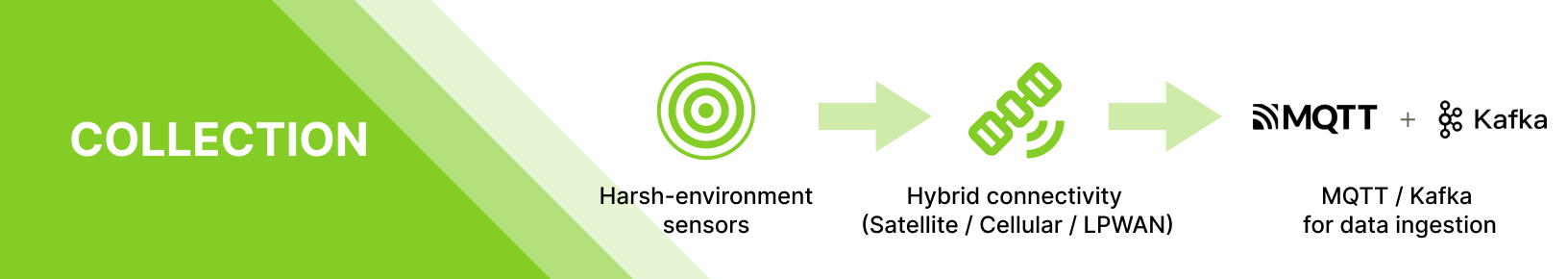

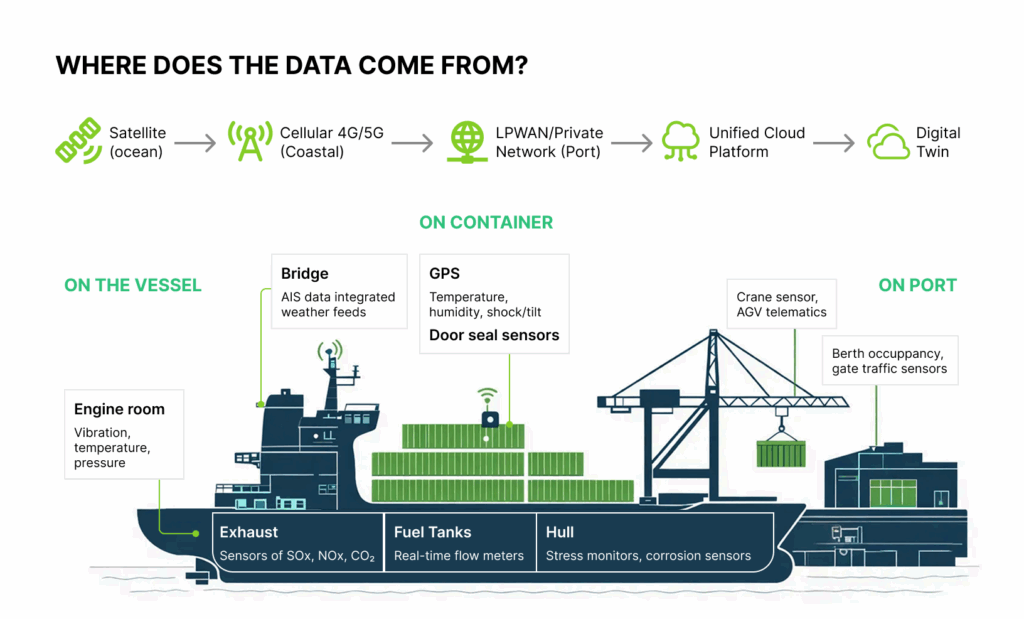

Devices & Connectivity

Ships and vehicles use IoT sensors like GPS, engine-monitoring modules, environmental sensors, RFID card readers at fueling stations. All sensors must withstand harsh conditions and connectivity must be hybrid.

Offshore links rely on satellite or long-range radio (like mesh networks), while near-shore and port areas can use cellular (LTE/5G) or private networks. LPWAN technologies (LoRa WAN, NB-IoT) are popular for low-bandwidth needs like buoy monitoring. Designing for intermittent connectivity and store-and-forward data is key at sea.

Data Ingestion

Tens of thousands of readings per second) flow into cloud or on-premise servers. Time-series databases (like TimescaleDB) are ideal here, as they handle millions of rows per minute. For example, TimescaleDB (a PostgreSQL extension) partitions and compresses historical sensor data. Data pipelines often use MQTT or Kafka for reliable transport and to buffer data when links drop. Integration layers pull in Automatic Identification System ship positions, weather forecasts, and port schedules via APIs.

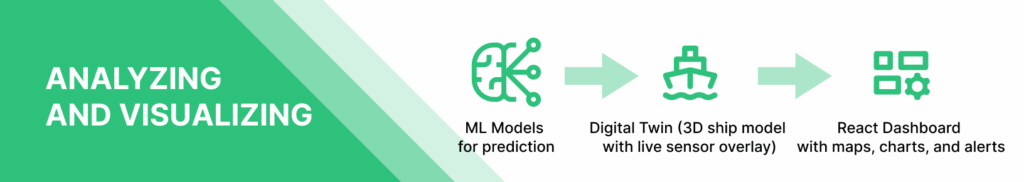

Analytics

On top of raw data, platforms run analytics engines. Real-time rules generate alerts (e.g. engine overheating) and visualization data (like aggregations, health scores). Machine learning models predict component failures or optimal fuel-saving routes. All this runs as microservices or cloud functions, containerized with Docker/Kubernetes. The architecture must support multi-tenancy and security.

User Interfaces & Visualization

Results are in web/mobile dashboards built with frameworks like React and APIs for integration. Dashboards display real-time maps, charts, and even 3D vessel models. For example, operators can view a 3D “digital twin” of a ship where sensor markers change color by health status. Clicking on a marker brings up detailed diagnostics in seconds. Some solutions even support augmented reality. A tablet could overlay IoT data onto a live camera view of a vessel. The UI must be intuitive for rapid decision-making.

Integration and Security

IoT platforms tie into existing enterprise systems via APIs or middleware. Standards like OPC-UA or MQTT and open data formats (JSON) ease this. Devices and data channels use TLS encryption, and the platform enforces IAM, network segmentation, and IoT-specific cybersecurity best practices. On the operations side, the solution should co-exist with existing SCADA/PLC systems.

Implementation Tip

- Begin with high-value assets like principal vessels or critical fuel tanks and expand IoT coverage gradually.

- Use edge computing where possible to filter data onboard, reducing bandwidth needs.

- Select sensors, DB, frontend frameworks that support interoperability to avoid vendor lock-in.

- As an example, our yacht monitoring dashboard used a React front-end with PostgreSQL + Timescale on the backend for robust, real-time performance.

Case Studies

Integrated Fleet Optimization and Monitoring

Our team delivered an end-to-end maritime IoT platform Marine Fields that aggregates data from vessels, cargo, and external sources into unified dashboards. As a SaaS solution, it pulls in internal sensor feeds plus external feeds and visualizes everything on maps and reports. Users get instant alerts and a comprehensive view.

For example, each ship has a 3D deck model overlaid with sensor positions, and real-time weather and GPS coordinates are shown on Google maps. Advanced analytics optimizes routes and maintenance schedules. This platform achieved a significant performance boost for our client’s fleet.

Vessel efficiency improved through data-driven insights, and the solution even won a SMART4SEA award.

Yacht Monitoring Dashboard

In another project, we developed a yacht system. The system processes very large volumes of data. It uses React for the frontend and PostgreSQL + TimescaleDB for the backend. The solution receives data streams from sensors and GPS and displays them on the dashboard. We optimized the data resources for largest performance, ensuring users always see up-to-date information.

The “Diptychs” dashboard also includes 3D models of the yacht. They graphically display current values, temperature, and battery status on each deck. This 3D visualization provides operators with a clear overview of all components at a glance.

The result is a IoT application that facilitates operational monitoring and data processing.

Diesel Fuel Management System

We also implemented a fuel management solution for industrial sites and mobile refueling operations. In this system, drivers carry personalized cards linked to their vehicle and client account. Upon refueling, the card is scanned and the system debits the exact liters delivered from the client’s account.

It then generates invoices for actual fuel consumed without manual paperwork and errors. The platform also monitors remote tank levels. When a tank runs low, it signals for replenishment.

This digitization of fuel logistics means the company gained real-time visibility into thousands of diesel tanks and feeling events. Clients enjoy precise billing and reduced loss, while site managers use the data to optimize inventory and scheduling.

Conclusion

The above examples illustrate how IoT can transform maritime and logistics operations. By connecting assets and analyzing data in real time, companies achieve clear ROI. IoT also boosts safety and compliance. Standards. Investing in IoT and analytics pays dividends in efficiency and competitiveness.

If your organization isn’t yet exploiting these opportunities, now is the time. We have deep experience deploying integrated IoT platforms. Let’s discuss how IoT can plug into your existing systems and deliver real-time insights for better decision-making.

Contact us to explore tailored solutions that will drive your operational excellence and deliver measurable ROI.

Modern maritime and logistics operations are under pressure to be more efficient. IoT offers a way to transform fleets by connecting ships, trucks, containers, and infrastructure. With IoT companies gain real-time visibility into location, engine performance, fuel use, and environmental conditions. This visibility shifts operations from reactive to predictive. It also enables faster decision-making and […]

AKDev Group is a leading software development company in Georgia. 2025 was a year of deep specialization. If I could sum it up in one phrase, it would be “from recognizing competencies to scaling them.”