What Is the Best Logistics Software?

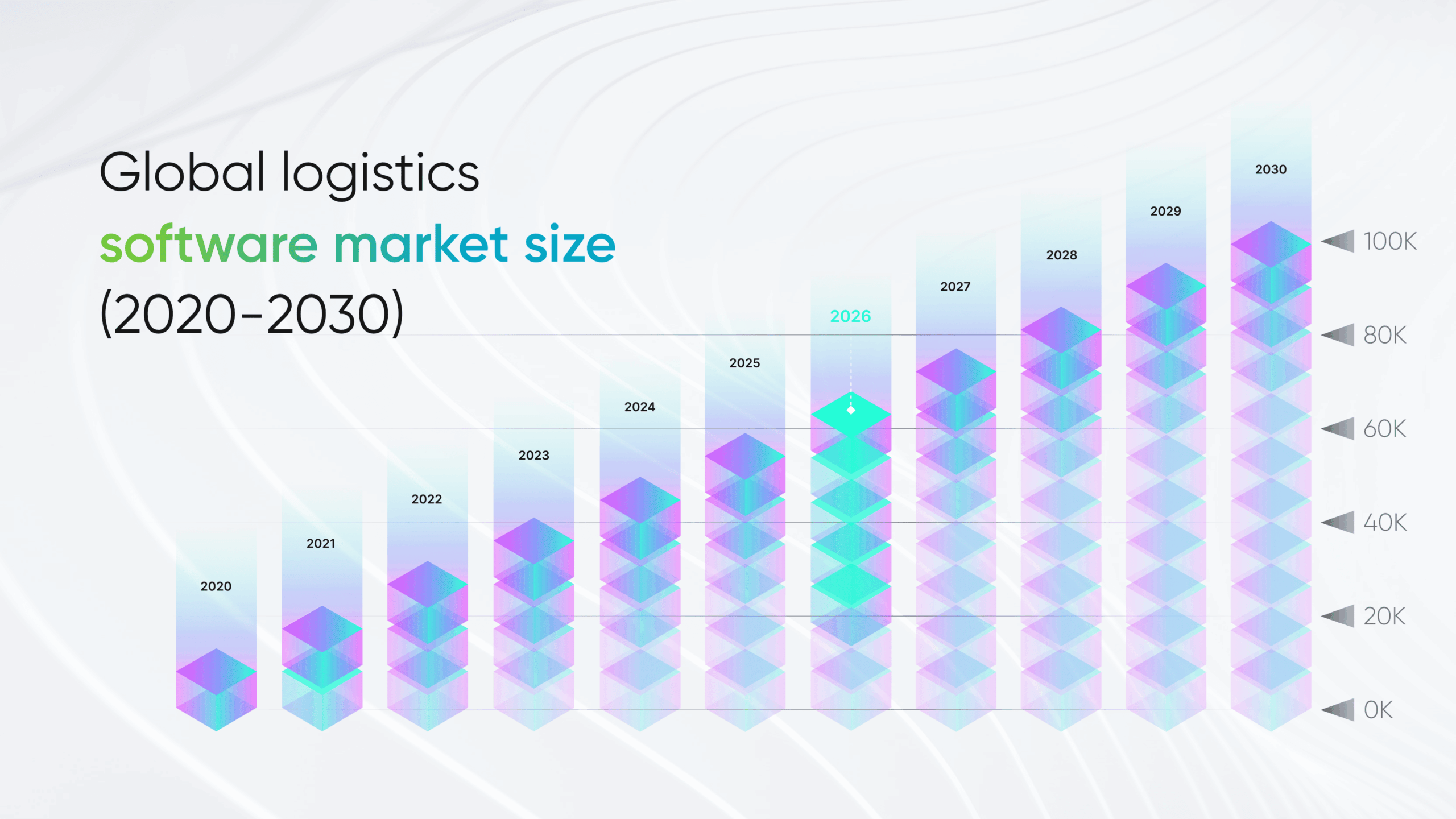

Managing supply chains today relies on specialized software. Experts valued the global logistics software market at about $17.7 billion in 2024 . Analysts expect it to reach $40 billion by 2033. The explosion of e-commerce (global sales hit $5.7 trillion in 2022) drives this growth. Modern logistics tools often leverage AI, IoT, and analytics to cut costs and improve delivery times.

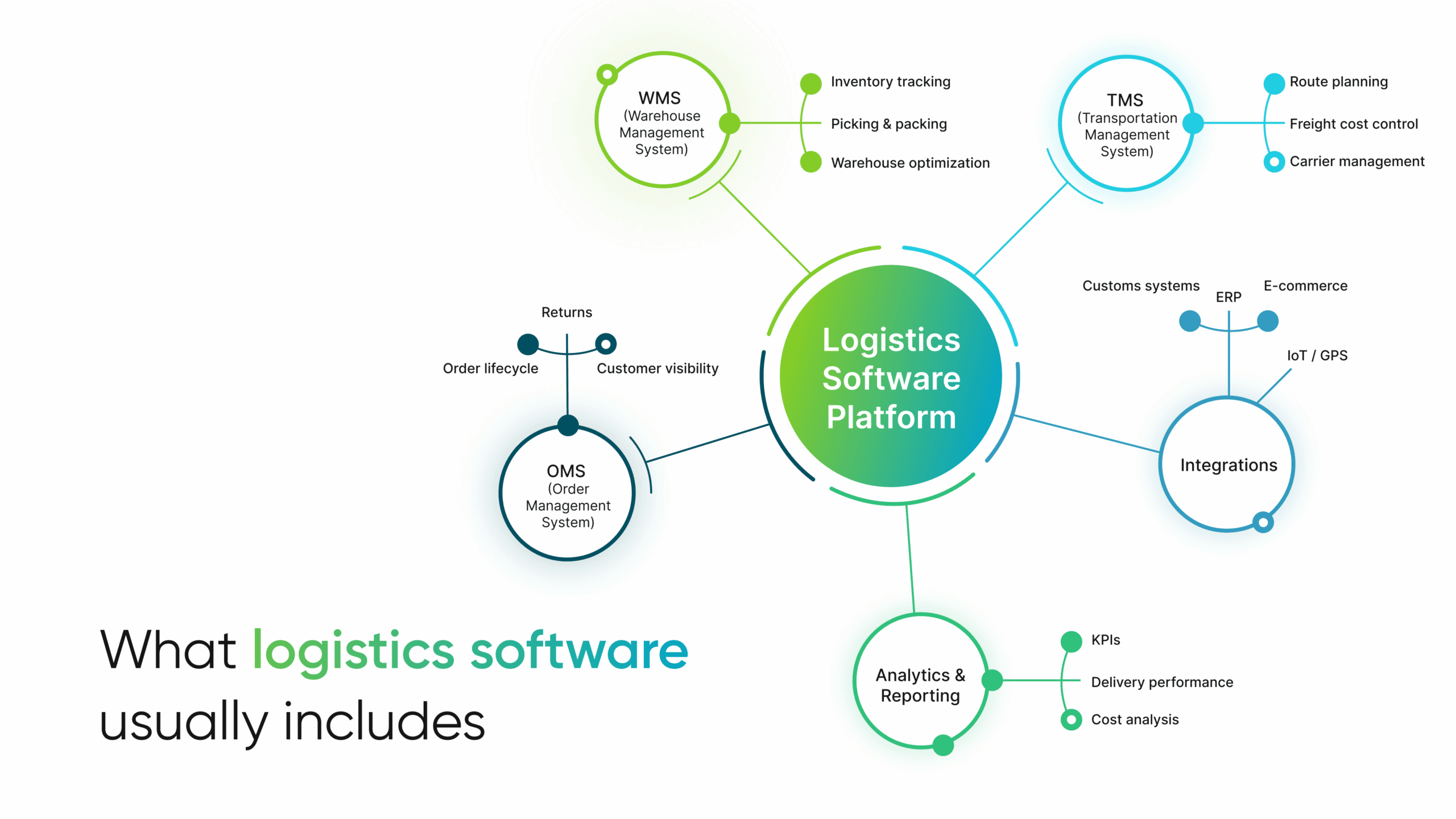

Logistics software includes modules like TMS (Transportation Management Systems), WMS (Warehouse Management Systems), and OMS (Order Management Systems). 𝗧𝗠𝗦 helps plan, control, and optimize transportation. Companies use TMS to create routes, select carriers, track cargo and reduce transportation costs. 𝗪𝗠𝗦 optimizes receiving, storage, shipping, and inventory. WMS helps reduce costs and speed up order processing.

Also there are:

- 𝗙𝗠𝗦 allows you to track vehicle location, check fuel consumption, vehicle condition, and driving performance.

- 𝗖𝗥𝗠 for logistics manages customer interactions, from order processing to delivery tracking. CRM helps improve service and increase customer loyalty.

- 𝗘𝗥𝗣 integrates finance, logistics, sales, and HR. ERP provides complete supply chain visibility, and helps make informed decisions.

- 𝗦𝗖𝗣 uses data for demand forecasting, production planning, and logistics optimization. SCP helps synchronize supply and demand.

- 𝗪𝗘𝗦 coordinates automated and manual warehouse processes, ensuring efficient order fulfillment.

- 𝗗𝗢𝗠 synchronizes online and offline deliveries and prevents errors such as double booking.

Each helps businesses track shipments, manage stock, and coordinate deliveries. The best choice depends on your company’s size, complexity, and goals.

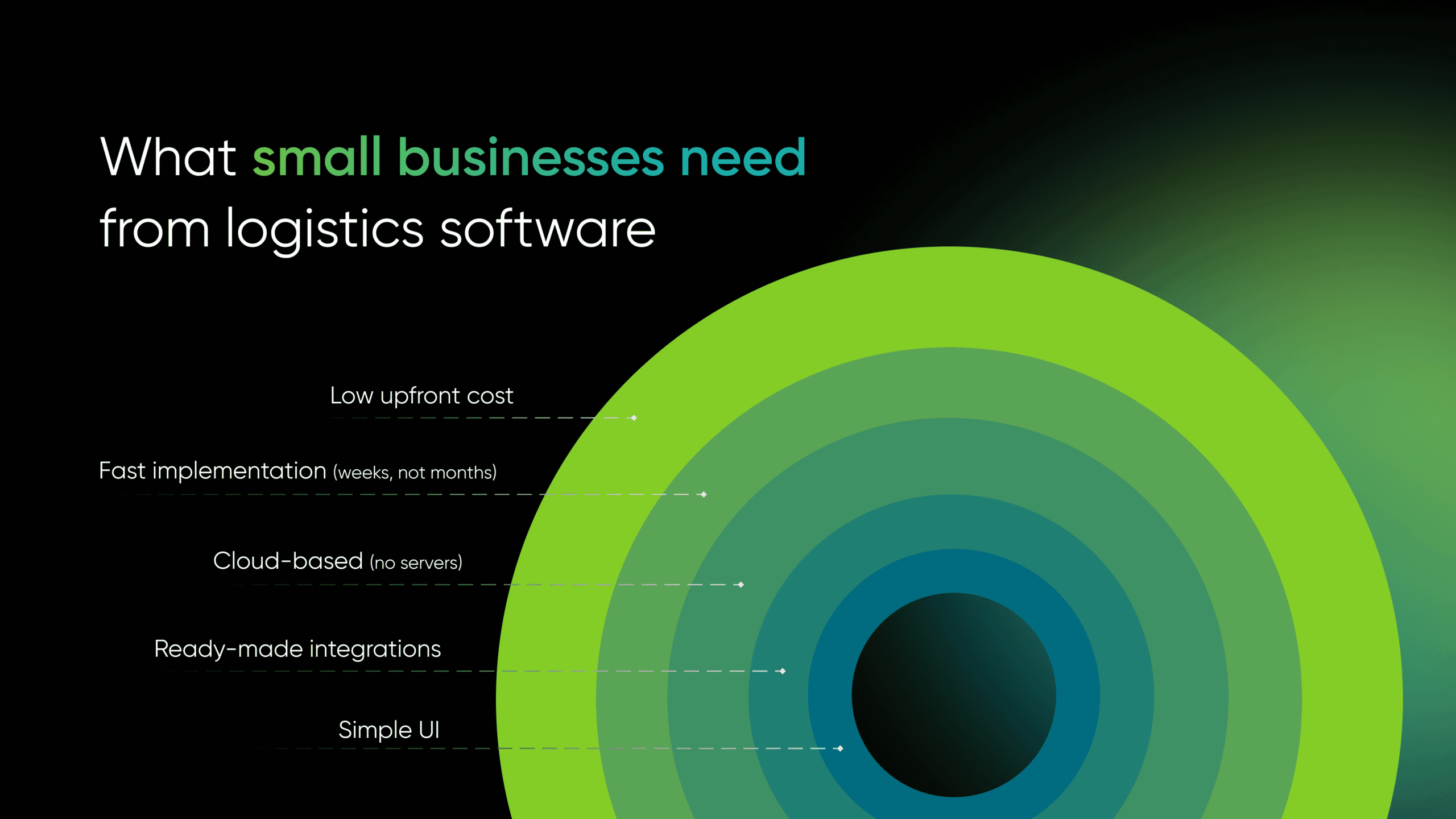

Options for Small Businesses

Small businesses often focus on affordability and ease of use. Many use cloud-based platforms that bundle common logistics features. In fact, a recent survey found over 50% of small shippers already use WMS, TMS, or fleet-management software. These tools automate tasks like label printing, real-time shipment tracking, and basic inventory control. Key considerations for small companies include pay-as-you-go pricing and quick setup.

- Inventory tracking, multi-carrier shipping, and order management in one dashboard.

- SaaS solutions cut upfront cost and maintenance.

- Look for monthly subscriptions or tiered plans that fit smaller shipping volumes.

- User-friendly interface and responsive customer support are important.

- Built-in connections to couriers, e-commerce platforms, and accounting systems.

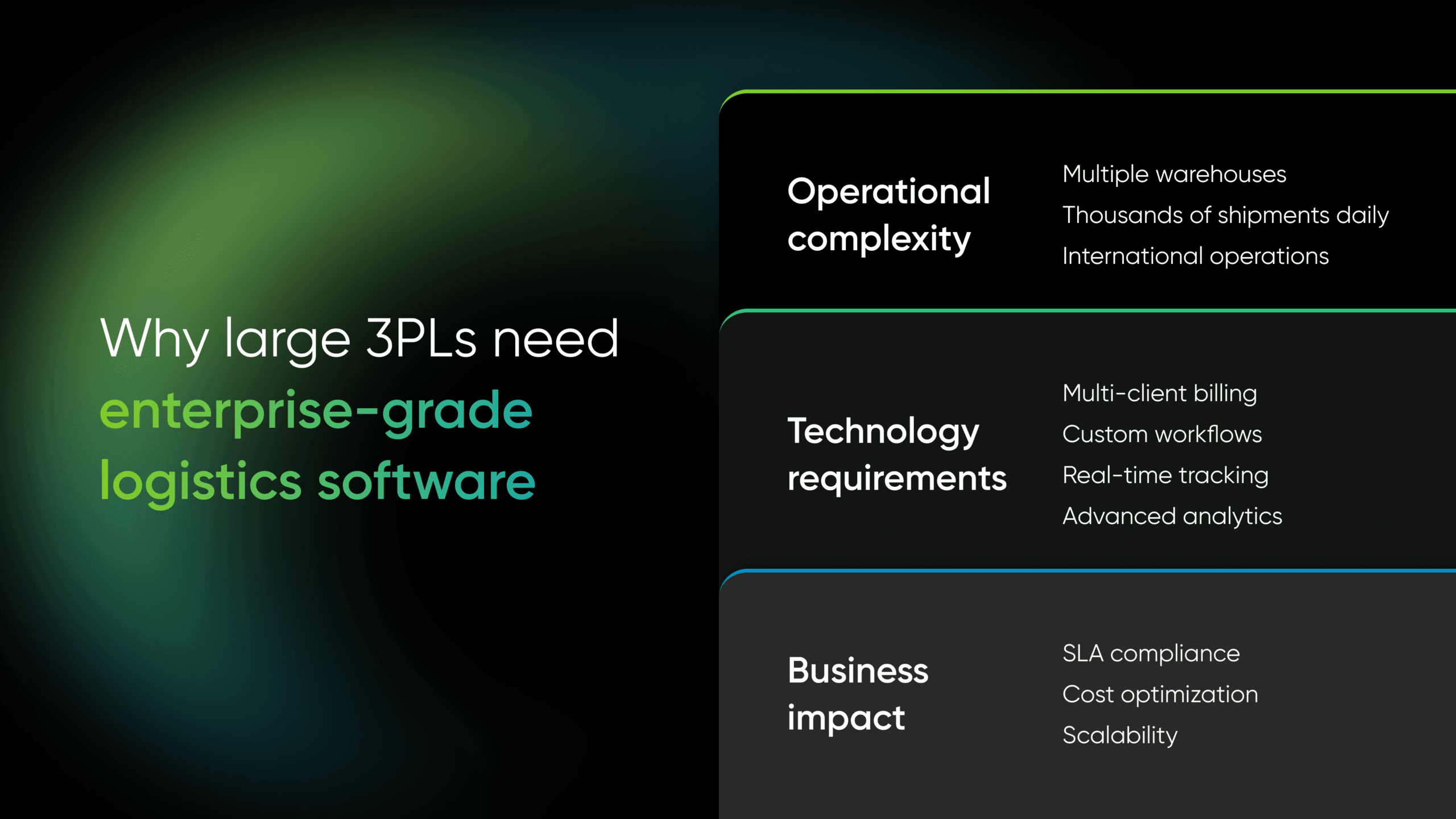

Options for Large 3PL Providers

Third-party logistics (3PL) companies handle hundreds of clients and vast shipping volumes. They need enterprise-grade software. Analysts estimated the global 3PL software market at about $7.7 billion in 2024. Large 3PLs often use platforms like SAP, Oracle, Manhattan or specialized WMS/TMS.

- Support for many warehouses, vehicles, and users across regions.

- Automated invoicing based on complex contracts and usage metrics.

- Ability to configure processes for cross-docking, kitting, reverse logistics, and other advanced operations.

- Performance dashboards for KPIs (on-time delivery, use, cost per shipment).

- Real-time links to ERP systems and customer order platforms for full visibility.

- Often a hybrid of cloud and on-premises, balancing security with global access.

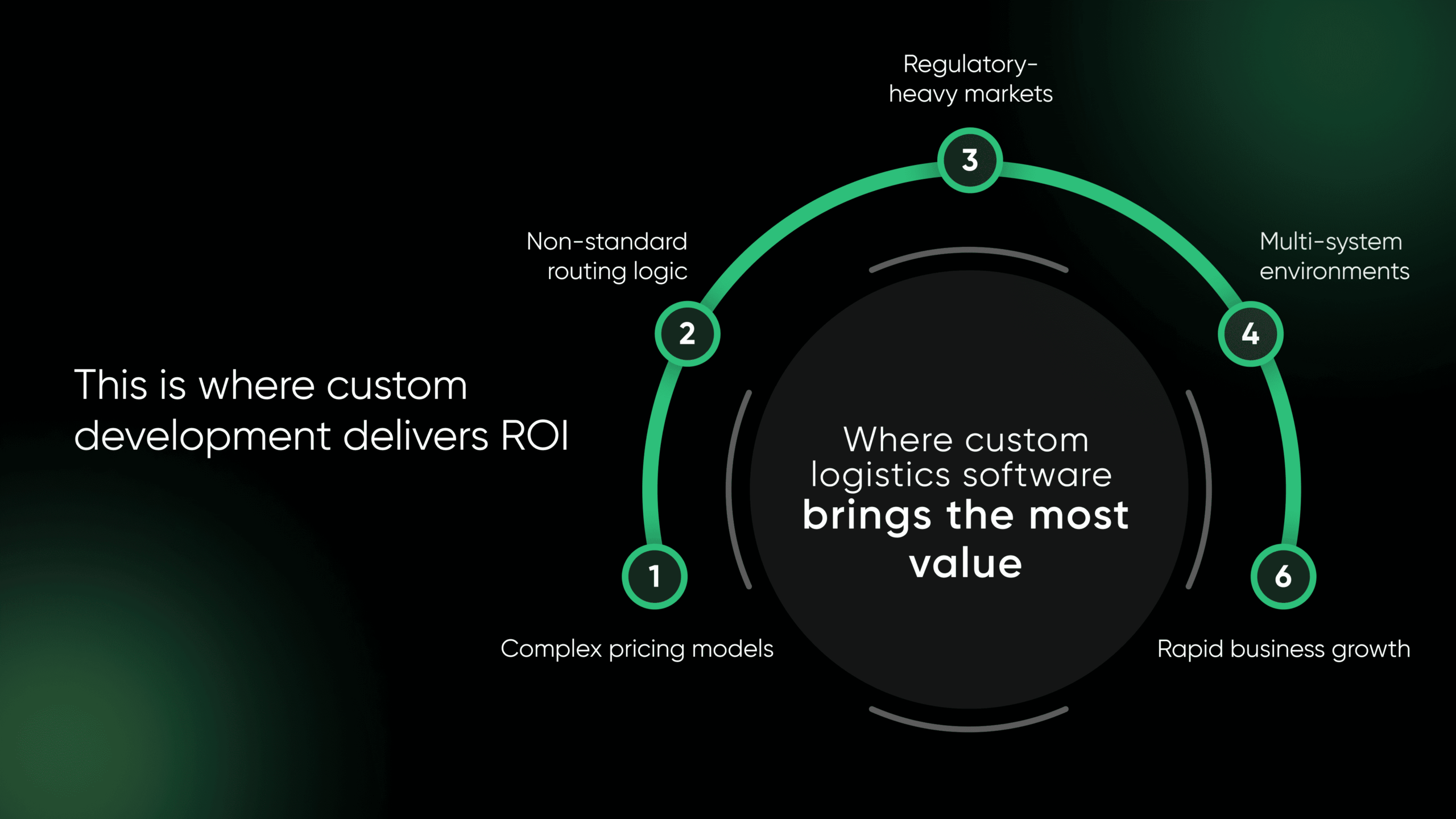

When to Consider Custom Development

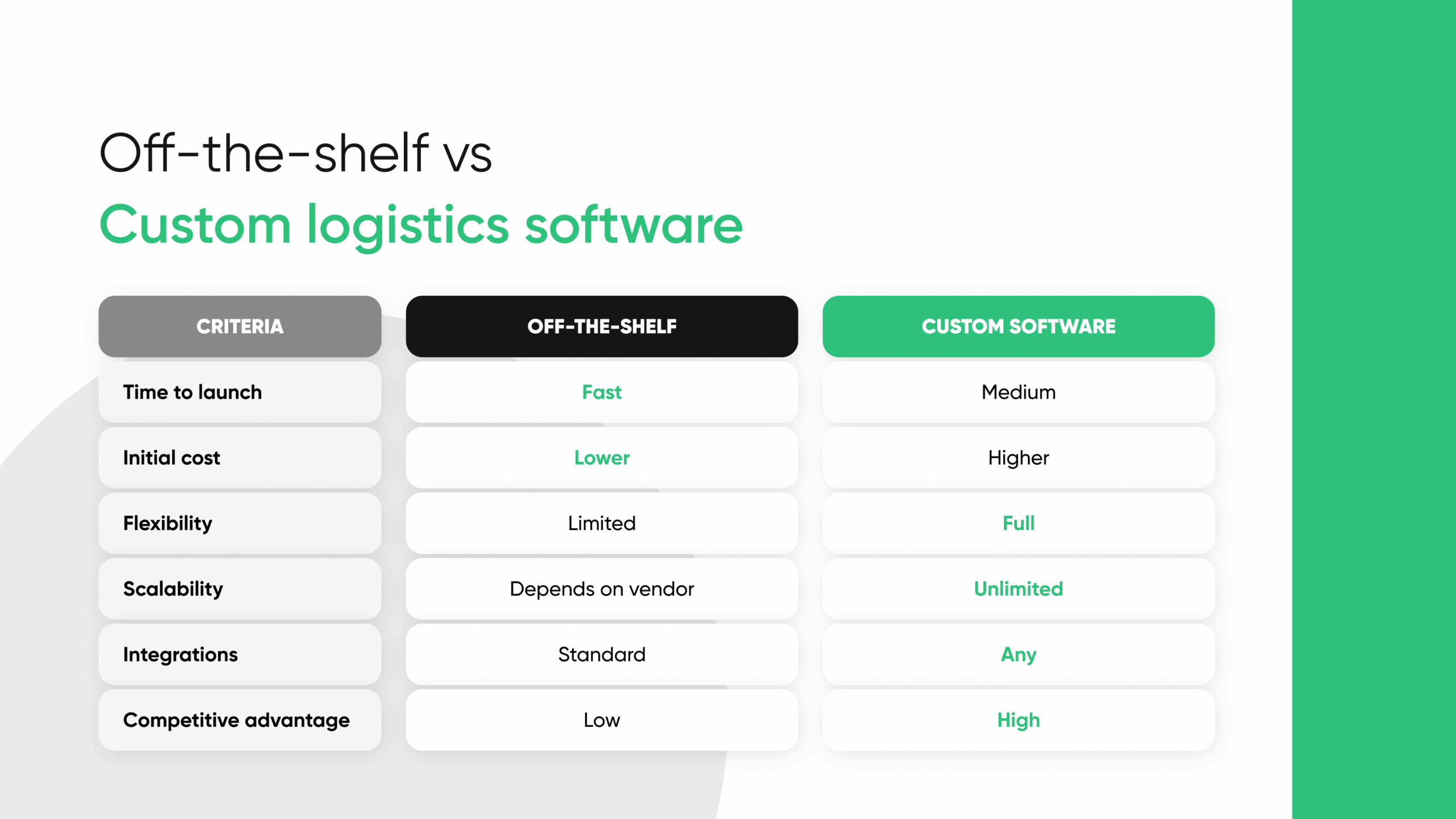

Off-the-shelf software covers many needs. But custom development can be the best choice if your logistics processes are unique. For example, a company with proprietary routing algorithms may find standard tools insufficient.

A custom logistics system can automate exactly the processes you use and adapt as you grow. Many businesses that choose custom development see long-term gains. They don’t pay no per-user fees, no workarounds, and a system that evolves with their needs.

Сustom development requires more time and investment. It makes sense when:

- Your processes or rules are one-of-a-kind (standard products can’t be bent to fit).

- You need deep integration with ERP, databases, IoT devices that off-the-shelf tools can’t match.

- You’re seeking a competitive edge. A custom system can differentiate your service.

Choosing the Right Solution

Every buyer journey starts by learning about options, then comparing features, and finally making a decision.

Firstly, focus on understanding your core needs. Do you need to increase shipping volume, number of warehouses, complexity of orders, or optimise budget. Then, compare software demos or vendor case studies to see what fits best. Finally, calculate total cost of ownership (licenses, maintenance, training).

There is no single best software for every company. Small businesses with simpler needs find that an off-the-shelf WMS/TMS platform is the most practical solution. Large 3PLs need full-featured systems or even many integrated tools. If no existing product matches your unique workflow, custom development is worth considering.

We develop custom logistics systems. Check out our portfolio with similar cases to see examples of tailored solutions. They helped our clients optimize their supply chains.

Modern maritime and logistics operations are under pressure to be more efficient. IoT offers a way to transform fleets by connecting ships, trucks, containers, and infrastructure. With IoT companies gain real-time visibility into location, engine performance, fuel use, and environmental conditions. This visibility shifts operations from reactive to predictive. It also enables faster decision-making and […]

AKDev Group is a leading software development company in Georgia. 2025 was a year of deep specialization. If I could sum it up in one phrase, it would be “from recognizing competencies to scaling them.”